- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

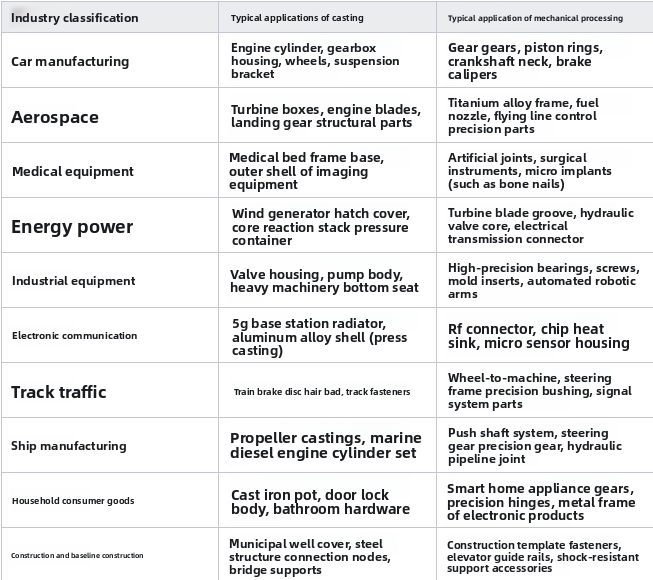

Where are casting and machining used?

2025-08-20

Where are casting and machining used?

Advantages of Machining: High Precision: Multi-axis CNC technology enables micron-level precision control, making it particularly suitable for complex parts with stringent dimensional requirements, such as turbine blades and medical implants. Rapid Response to Small-Batch Demand: Eliminating the need for complex mold development, machining can be performed directly from design files, significantly shortening prototype verification and small-scale production cycles. Stable Repeatability: CNC programs and standardized tool paths ensure consistent part dimensions and surface quality throughout mass production. Automated Production: CNC systems automate the entire process, reducing manual intervention, minimizing operational errors, and improving continuous equipment efficiency. Wide Material Compatibility: Compatible with metals, engineering plastics, ceramics, and composites, meeting the diverse material performance requirements of various industries.

Disadvantages of Machining: Limited Internal Structure Processing: Complex internal features such as deep holes and cavities require multiple tool changes or custom tooling, significantly increasing processing difficulty and cost. Dimensional Constraints: Limited by machine tool travel and spindle rigidity, precision machining of oversized or heavy workpieces is difficult.

Low resource utilization: The cutting process generates large amounts of metal shavings or dust, resulting in a higher rate of raw material loss than additive manufacturing or near-net-shape processes. Machining and Casting: Types and Technologies Processing

Types: Milling: Utilizes a rotating multi-edge tool to cut the workpiece along multiple axes. Suitable for machining flat surfaces, curved surfaces, and complex three-dimensional structures, it is widely used in mold cavities and the manufacture of special-shaped parts.

Turning: By combining workpiece rotation with the tool's linear feed, it efficiently forms rotating parts (such as shafts and sleeves), capable of machining external diameters, internal bores, and threads. Drilling: A spiral drill bit is used to penetrate the material to form a circular hole. It supports the machining of through holes, blind holes, and stepped holes, and is commonly used for the mass production of locating holes for component assembly. Grinding: A high-speed rotating grinding wheel is used to perform micro-cuts on the workpiece surface, improving dimensional accuracy and finish. It is suitable for tool edge resurfacing and high-precision bearing raceway machining. Boring: A single-edge boring tool is used to expand the inner diameter of a pre-drilled hole, precisely controlling the hole's coaxiality and cylindricity. It is commonly used for machining precision internal cavities such as engine blocks and hydraulic valve bodies. Broaching: Use a broach with a multi-stage tooth profile to form keyways, splines, or special-shaped internal holes in one go. This method is highly efficient and offers stable surface quality, making it suitable for the mass production of gears and couplings. Wire Cutting: Cuts conductive materials using the principle of electroerosion.

It can process complex contours of superhard metals and is particularly suitable for precision stamping dies and aerospace engine blade forming. Planing: The tool uses linear reciprocating motion to cut planes or grooves. This method is suitable for plane machining of guide rails and base plates of large machine tools. It is simple to operate but relatively inefficient.

Electrospark Machining: Utilizes pulsed discharge to corrode conductive materials. It can process micro-holes, complex cavities, and carbide molds, breaking through the hardness limitations of traditional cutting. Each process is combined and applied based on tool characteristics, motion trajectory, and material adaptability, collectively covering the needs of the entire industry chain, from rough machining to ultra-finishing. Casting Types: Sand Casting: Silica sand, clay, or resin binders are used to create one-time or semi-permanent molds. The mold cavity is formed by imprinting the model. This method is suitable for the diversified production of high-melting-point metals such as cast iron and cast steel.

It is commonly used in the manufacture of structural components such as engine blocks and valves. Die casting: Molten metal is pressed into a high-strength steel mold at high speed, rapidly cooled and formed. It specializes in the mass production of precision thin-walled parts of non-ferrous metals such as aluminum, zinc, and magnesium, and is widely used in products with high surface finish requirements such as automotive parts and electronic housings. Investment casting: A wax mold is used instead of a physical model, coated with multiple layers of refractory coating to form a ceramic shell. The lost wax mold is melted and then injected with molten metal. It can replicate complex and delicate structures such as turbine blades and artworks, and is particularly suitable for small-batch customization of high-temperature alloy parts in the aerospace field. Centrifugal casting: Using centrifugal force to evenly adhere the molten metal to the inner wall of the rotating mold, it forms rotationally symmetrical parts such as seamless pipes and hubs. It combines material density and production efficiency and is mostly used in the production of pipes and bearing rings. Low-pressure casting: Liquid metal is smoothly injected into a closed mold through air pressure to reduce turbulence and oxidation. It is used to form hollow parts with high density requirements such as aluminum hubs and cylinder heads, and has the advantages of both process stability and material utilization. Lost-foam casting uses a foam plastic pattern instead of a traditional mold. During pouring, the pattern vaporizes and is filled with molten metal, allowing for the integrated production of castings with complex internal cavities. This method is suitable for single-piece or small-batch production of products such as mining machinery and pump and valve housings. Continuous casting involves continuous solidification of molten metal through a water-cooled mold and casting, directly producing bars, plates, or profiles.

This significantly improves the molding efficiency of materials such as steel and copper alloys, and has become a core process for large-scale production in the metallurgical industry. Each casting technique is tailored to mold characteristics, metal fluidity, and production needs, resulting in comprehensive manufacturing capabilities ranging from artistic castings to industrial components. Key differences between machining and casting: Tooling characteristics: Machining relies on cutting tools such as milling cutters, drills, and lathes to directly shape parts, while casting requires preliminary processes such as model making and mold preparation to create the molding space. The tool chain covers the entire process, from wax carving to sand mold preparation. Precision-controlled machining uses CNC systems to achieve micron-level accuracy and is particularly adept at achieving high surface finishes and complex geometric details. Castings, however, are affected by factors such as mold accuracy and metal shrinkage, requiring precision die casting or investment casting to achieve dimensional consistency.

Material compatibility: Casting materials are limited by their melting point and fluidity. Sand casting is suitable for high-melting-point metals such as cast iron and cast steel, while die casting focuses on low-melting-point alloys such as aluminum and zinc. Machining can process a wide range of materials, including metals, engineering plastics, and ceramics, with a wider range of hardness. Design complexity: Machining excels at forming sharp edges, thin-walled structures, and precise holes and slots, but has limitations when processing closed structures such as deep cavities and inward curves. Casting can form complex components with internal cavities and curved streamlines (such as engine blocks) in one piece, but details are less sharp. Production scale: Casting offers cost advantages in large-scale production, and molds can be quickly replicated after a single investment. Machining requires no molds and can accommodate small-batch or single-piece customization requirements through program adjustments, offering greater flexibility.

Part performance: Machined parts have more uniform mechanical properties due to the absence of solidification defects. Castings, through processes such as directional solidification and heat treatment to optimize the grain structure, can approach the strength of the original material, but may contain microscopic pores or inclusions. Prototype development efficiency: Machining directly cuts from CAD models, completing prototype trials within hours. Casting prototypes require mold development and metal pouring, which takes a long time, but investment casting can accelerate the process by using 3D-printed wax patterns.

The overall cost structure of casting is high in the initial mold costs, making it suitable for scale production to dilute the cost per piece. Machining, on the other hand, has no mold costs, and material loss and labor costs increase linearly with batch size, making it more suitable for small- to medium-sized or high-value-added products. The two processes complement each other in the manufacturing industry: casting solves the mass production of complex components, while machining enables the final correction of precision features, jointly supporting the complete manufacturing chain from blank to finished product.